Why is 316 stainless steel plate corrosion-resistant?

Chromium’s Role in Forming the Protective Passive Layer

How Chromium Content Enables Corrosion Resistance in 316 Stainless Steel

What makes 316 stainless steel plates so resistant to corrosion starts with their chromium content, typically around 16 to 18 percent in the alloy mix. When these plates come into contact with oxygen, the chromium reacts naturally to create a thin chromium oxide layer measuring roughly 2 to 3 nanometers across. This protective film serves as sort of electrochemical shield that stops things like chloride ions from getting to the actual metal underneath. Most stainless steels need at minimum 10.5% chromium to show some level of corrosion protection, but because 316 contains more chromium, it forms this protective layer quicker and lasts longer too. That's why many industrial applications prefer 316 over other grades when dealing with harsh environments.

Formation and Stability of the Chromium Oxide (Cr₂O₃) Passive Film

The Cr₂O₃ film forms spontaneously through oxidation at ambient temperatures, with stability dependent on environmental conditions:

| Factor | Optimal Range for Film Stability |

|---|---|

| Oxygen levels | ≥0.1 ppm |

| pH | 4.5–8.5 |

| Temperature | -50°C to 300°C |

In neutral environments, the oxide layer remains stable indefinitely. However, acidic conditions (pH <4) or sustained exposure above 300°C can compromise film integrity, increasing reliance on molybdenum and nickel for protection.

Self-Repairing Ability of the Passive Layer in Oxidizing Environments

If the Cr2O3 layer gets damaged somehow, it actually has this neat ability to fix itself when there's oxygen around. The chromium in the main part of the alloy moves over to wherever the surface is exposed and starts reacting pretty quickly to rebuild that protective coating. Sometimes this whole repair process happens within just a few hours. This kind of self healing really matters in places like chemical processing plants. Those environments are tough on materials because all sorts of things happen - parts rub against each other, temperatures swing up and down constantly, which can all chip away at surfaces over time. Without this automatic repair mechanism, equipment would need much more frequent maintenance and replacement.

Chromium Comparison: 316 vs. 304 Stainless Steel Plates

Although both grades rely on chromium-induced passivation, 316 contains 16–18% chromium compared to 304’s 18–20%. Despite slightly lower chromium content, 316’s inclusion of molybdenum allows it to maintain passive film stability in chloride-rich environments where 304 fails. Independent testing shows 316 resists salt spray corrosion 4–6 times longer than 304 under identical conditions.

Molybdenum’s Contribution to Enhanced Chloride Resistance

Adding about 2 to 3 percent molybdenum to 316 stainless steel gives it much better protection against damage from chlorides. What happens is that molybdenum stops corrosion from starting up in specific spots. It does this by creating these stable molybdate ions MoO4^2- right where there are defects on the metal surface, which basically stops pits from forming. According to some research done back in 2001 by Ilevbare and others, this molybdenum addition actually boosts what they call the pitting resistance equivalent number (PREN) by around 35%. That's pretty significant when compared with regular old 304 stainless steel that doesn't have any molybdenum added to it.

How Molybdenum Improves Resistance in Chloride-Rich Conditions

In marine environments with chloride concentrations exceeding 19,000 ppm, molybdenum promotes uniform passive film development. Accelerated corrosion testing (ASTM G48 Method A) shows it reduces metastable pitting events by 72% in saline solutions, significantly delaying the onset of visible corrosion.

Inhibition of Pitting and Crevice Corrosion by Molybdenum Alloying

Molybdenum enhances localized protection by migrating to micro-defects and forming corrosion-resistant barriers that:

- Limit chloride ion penetration below critical thresholds (<0.1 ppm free Cl⁻)

- Reduce pit propagation rates by 58% in pH 4–9 environments

- Maintain oxide layer integrity up to 60°C in stagnant seawater

Real-World Performance: 316 Stainless Steel in Marine and Coastal Environments

Field studies of coastal infrastructure show 316 plates sustain corrosion rates below 0.002 mm/year after over two decades of salt spray exposure. In tidal zones, this performance exceeds 304 stainless steel by a 4:1 margin, due to molybdenum’s synergistic reinforcement of the chromium oxide layer under wet/dry cycling.

Synergistic Effects of Nickel and Overall Alloy Composition

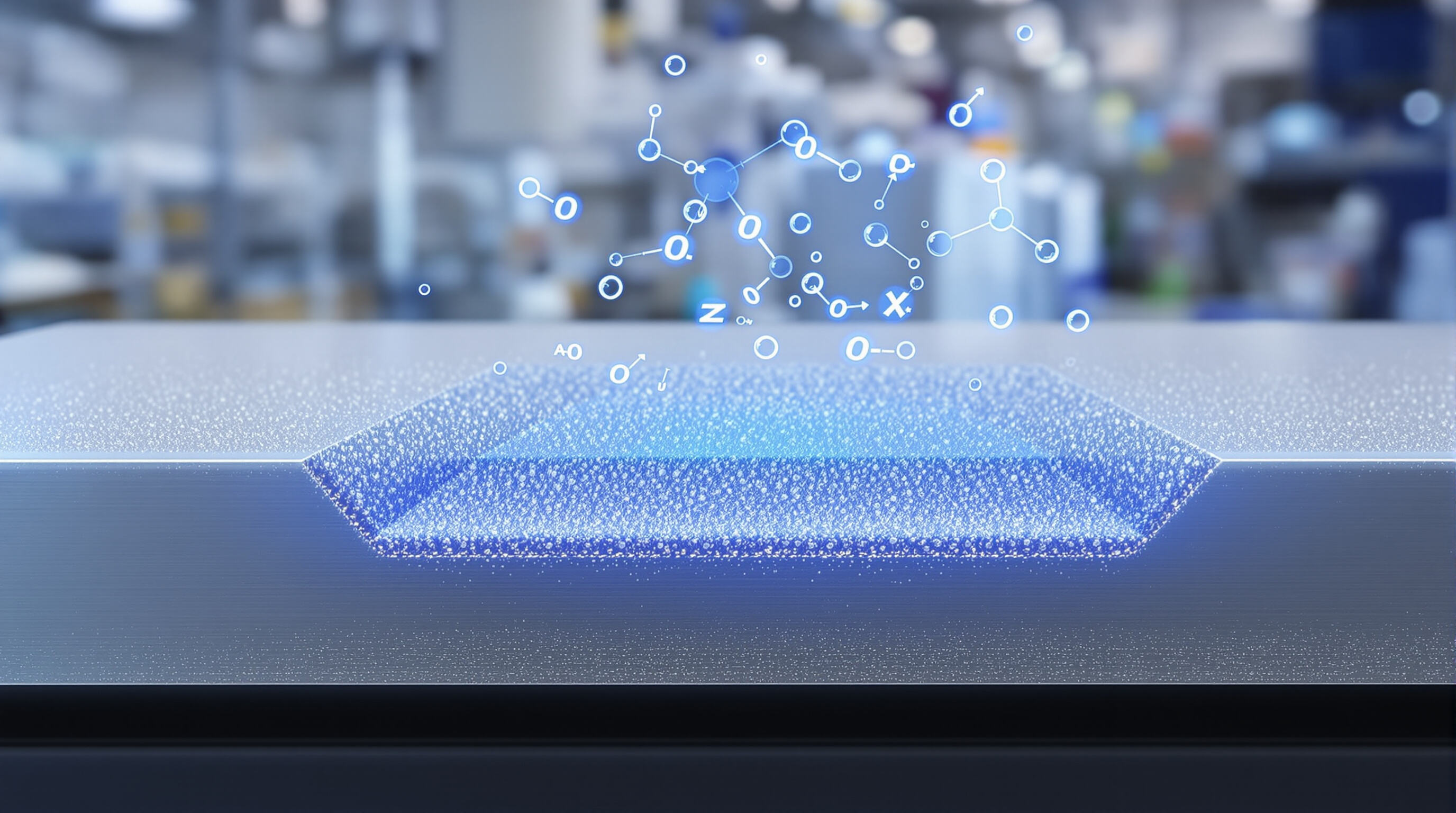

Chemical composition breakdown of 316 stainless steel plate (Fe, Cr, Ni, Mo, C)

316 stainless steel consists of 16–18% chromium, 10–14% nickel, 2–3% molybdenum, less than 0.08% carbon, and iron as the base (68–72%). This balanced formulation enables complementary interactions: chromium enables passivation, nickel stabilizes structure, and molybdenum counters chlorides—a synergy validated in metallurgical studies of nickel-based alloys.

How nickel enhances ductility and supports corrosion resistance

Nickel imparts exceptional ductility through its face-centered cubic crystal structure, allowing 316 plates to be formed into complex shapes without cracking. It also prevents stress corrosion cracking by stabilizing the austenitic phase at low temperatures and improving adhesion between the passive layer and base metal, reducing vulnerability at interface boundaries.

Alloy synergy: Interplay between chromium, nickel, and molybdenum

The corrosion resistance of 316 stainless steel exceeds the sum of individual element contributions:

- Chromium oxides form the primary protective barrier (Cr₂O₃)

- Nickel promotes surface enrichment of chromium by suppressing iron oxidation

- Molybdenum seals micro-defects via precipitation of MoO⁴²⁻ ions

This multi-level defense system makes 316 ideal for demanding applications in chemical processing and marine environments where single-element protection would fail.

Electrochemical Mechanism of Passive Film Formation

Spontaneous development of the oxide layer: Electrochemical principles

When 316 stainless steel comes into contact with oxygen, a Cr2O3 passive layer naturally develops on its surface. What happens is that chromium atoms at the surface grab onto oxygen molecules, which kickstarts the formation of an oxide film measuring around 2 to 5 nanometers thick within just a few minutes. According to what we know about materials science, this works through something called the Point Defect Model. Basically, there are gaps or vacancies in the oxide structure that let chromium keep moving from deeper inside the metal to the surface, so the protective layer can repair itself over time. Testing using electrochemical impedance spectroscopy shows these films stay stable for long periods. The numbers tell the story too – impedance readings regularly sit well above 500 kiloohms per square centimeter, indicating excellent protection against corrosion.

Environmental factors affecting passive film integrity (pH, temperature, oxygen)

Passive film performance depends on three key variables:

- pH: Acidic conditions (pH < 2) increase dissolution rates by 300% compared to neutral environments

- Temperature: Above 60°C, reduced oxygen solubility hampers self-healing

- Oxygen: Levels above 8 ppm support effective oxide regeneration

Studies in simulated marine environments highlight oxygen's role in maintaining electrochemical equilibrium at the metal-liquid interface, with optimal concentrations (8–12 ppm) enhancing long-term film durability.

FAQ Section

What is the role of chromium in 316 stainless steel?

Chromium in 316 stainless steel provides corrosion resistance by forming a protective chromium oxide layer on the surface, preventing chloride ions and other corrosives from reaching the metal beneath.

Why is molybdenum important in 316 stainless steel?

Molybdenum enhances resistance to pitting and crevice corrosion in chloride-rich environments, thus giving 316 stainless steel superior durability over 304 stainless steel.

What environmental conditions affect the passive film of stainless steel?

The integrity of the passive film can be compromised by acidic conditions, high temperatures, and insufficient oxygen levels.

How does nickel contribute to stainless steel's properties?

Nickel enhances ductility, stabilizes the structure at low temperatures, and supports the adhesion of the passive film to the base metal, which improves overall corrosion resistance.